Need a quote, sample, or more information about our products?

Contact us today and receive a response within 60 minutes during business hours.

Maintain the proper level of oil in your equipment with this self-leveling oiler, the LeveLock. When oil drops over time due to evaporation, burning, or leakage, the LeveLock replenishes oil as it is lost, and helps maintain the ideal level. As a leading levelock constant oil leveler supplier, ESCO Products is able to assist you in all your visual oil inspection needs.

The LeveLock constant level oiler is installed at the sight window that comes standard on most equipment. The 3-D Viewport allows for immediate visual indication of lubricant level and when the lubrication falls below the desired oil level, the reserve reservoir bottle on top self-levels, refilling the reservoir to its appropriate level. Maintaining the correct level and supply of lubricant is necessary to achieve an optimum state of machine reliability. Machines often fail due to too little or too much lubricant – the LeveLock pump and bearing oiler locks your oil level in place and provides you and your maintenance team peace of mind.

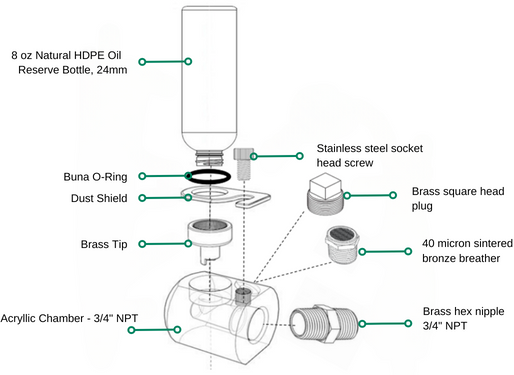

Esco LeveLock kit includes: 8 oz Natural HDPE Plastic Bottle, 24mm; Brass Tip, ¾” acrylic chamber, 1/8” NPT brass square head plug, 1/8” 40 micron sintered bronze breather vent, ¾” NPT brass hex nipple

What is a constant level oiler?

A constant level oiler is a device designed to maintain a consistent oil level in machinery by automatically replenishing oil as it is consumed or lost due to factors like evaporation, burning, or leakage.

How does the LeveLock work?

The LeveLock is installed at the side port of equipment, which typically has a viewport installed for users to monitor the oil level in the reservoir. As the oil level drops inside the machinery, the LeveLock backup oil reservoir backfills to replenish the lubricant to its proper operating oil level. This ensures a constant and reliable oil level.

How is the LeveLock different from other constant level oilers?

The LeveLock is self-leveling; it takes the guesswork out of marking the ideal oil level. Because the LeveLock is installed at the optimal oil level where the side viewport exists, there is no adjustment needed to ensure it maintains the correct level. Competitive products utilizing other equipment ports, like the drain port, often don’t function correctly because of user error during the installation process. The LeveLock leaves equipment drain ports available for other purposes. For example, a BS&W bowl or Hex-Duty Oil Sight glass could be installed at the drain port to collect and drain water contaminants.

Another big benefit is the product’s transparency allows operators to view the oil level in their equipment to confirm the product is operating as intended. Competitive products often have no way of verifying if they are operating correctly once installed.

The LeveLock reservoir bottle is offered in a sturdy HDPE plastic and the sight glass piece is made of an impact and stain-resistant cast acrylic. Other products often use glass which is fragile and not suitable for some applications like food processing. Acrylic withstands harsh outdoor conditions and a large temperature range of -40° to 230° F.

Finally, other products are often messy to refill, causing spillage. The LeveLock reservoir is easy to refill and flip into place onto the acrylic chamber without spilling a drop.

Where are constant level oilers commonly used?

Constant level oilers are widely used in various industrial applications, such as in gearboxes, bearings, and other machinery where a consistent oil level is crucial for optimal performance and longevity.

What are the benefits of using constant level oilers?

Some benefits include improved equipment lubrication, reduced maintenance requirements, extended machinery life, and prevention of damage caused by inadequate lubrication. Attentive operators may also identify pieces of equipment that are losing oil at a faster rate than expected and can then take corrective actions to identify the cause of the accelerated loss.

How do I choose the right constant level oiler for my application?

Consider factors such as the type of machinery, oil viscosity, ambient temperature, and the required oil flow rate. Consult with Esco Products directly to ensure compatibility with your specific needs.

Can the LeveLock be retrofitted onto existing machinery?

In most cases, yes. If the equipment has a side viewport (usually a flush-mounted bullseye sight window) on the equipment, the sight glass can be replaced with the LeveLock constant level oiler which is installed at the viewport. Currently, the LeveLock has a ¾” NPT installation port. Use caution when adapting to a smaller port size, as anything smaller than a ¾” NPT will cause pooling in the sight glass. The LeveLock will not function properly if installed on a port smaller than ½” NPT. Adapting to a larger port size will not cause any operating issues with the LeveLock.

How often should I inspect or maintain the LeveLock?

Regular inspections are recommended to ensure that the backup reservoir bottle has oil in it. If the lubricant in the backup reservoir bottle gets close to empty, it needs to be refilled to guarantee that the LeveLock can continue to operate as intended.

Can constant level oilers help with energy efficiency?

Yes, by maintaining optimal lubrication levels, constant level oilers contribute to energy efficiency by reducing friction and wear, leading to smoother machinery operation.

Is too much lubricant a problem?

Too much oil supplied to the bearings could increase friction, causing the operating temperature to rise and could lead to costly equipment repairs. The LeveLock’s simple design safeguards the equipment by providing the right amount of oil at the right time.

What are some other names for Constant Level Oilers?

Constant level oilers are known by various names depending on the manufacturer, however, here are some alternative names: Constant Level Lubricators, Automatic Oilers, Float Feed Oilers, Gravity Oilers, Automatic Lubrication Systems, Oil Level Regulators, Self-Regulating Oil Dispensers. Esco often refers to the LeveLock internally as the Drip Daddy.

Where can I purchase constant level oilers?

The Esco LeveLock can be purchased online at escopro.com/levelock or by contacting Esco at 800.966.5514 or info@esco-inc.com.